A CFD simulation of a restaurant with high ceilings concluded that thermodynamic diffusers helped improve thermal comfort and indoor air quality while saving 43% energy in heating. They were profitable as early as in the first year.

Introduction

When supplying air in the room for both heating and air conditioning, diffusers installed in ceilings higher than twelve feet are normally setup to supply a horizontal air jet in order to avoid reaching the occupied space with high velocity air drafts. High velocity jets combined with cold air temperature would create serious thermal discomfort for building occupants.

Although we might achieve a good balance of air mixing, temperature control, energy efficiency and thermal comfort in air conditioning, it is rarely the case when heating the space from the same diffusers.

The impact of buoyancy effect causing hot air to rise due to a difference in density increases with the height of the ceiling. The heated air jet coming out of the diffuser tends to rise and stick to the ceiling, creating stratification. Multiple factors influence the intensity of air stratification, such as ceiling height and diffusers’ installation height, angle of the air jet, temperature difference between supplied air and room air, and sources of heat loss such as doors, windows and walls.

Drawbacks of air stratification are a waste of energy, the inability to achieve occupants’ thermal comfort, and a lack of proper air mixing in the occupied space.

A common approach is to use ceiling fans (also called destratification fans) to push hot air near the ceiling downwards, towards the occupied space. Although the use of fans often makes it possible to reach the desired temperature at the thermostat or in the occupied space, extra air velocity caused by the fans is often a concern. Occupants can feel direct air drafts and variations in air temperature, two factors causing serious discomfort, mostly when sitting at the same location for a while.

Thermodynamic Diffusers

EffectiV HVAC’s thermodynamic diffusers have been on the market for many years now, successfully improving thermal comfort and energy efficiency in larger spaces with high ceilings. In addition to the positive feedback from engineers and building managers who have used the products, EffectiV’s engineering team wanted to quantify how much energy could be saved in heating.

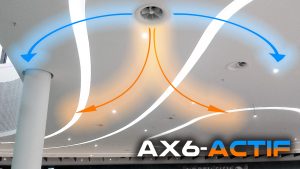

Thermodynamic diffusers use thermo-reactive materials in order to adjust the direction of the air jet based on the supplied air temperature. A thermal spring or thermal wax piston actuator is exposed to the air coming from the ventilation system and passing through the diffuser. The actuator expands or contracts, adjusting the diffuser’s airflow according to the supplied air temperature. The concept behind this mechanism is to diffuse cold air horizontally or upward, and hot air downward to compensate for the buoyancy effect causing hot air to elevate and saturate near the ceiling.

Three models of thermodynamic diffusers are available. DCG-ACTIF aluminum 3 cone round diffuser and AX6-ACTIF round swirl diffuser are both designed to be installed in high ceilings, while KAM-ACTIF nozzle jet diffuser is meant to be installed in the sidewall of larger rooms.

Thermodynamic diffusers are “plug-and-play” solutions which do not require electricity to operate, nor any special configuration or maintenance. They are installed like standard diffusers and operate autonomously.

The thermodynamic diffusers used in the current case study were AX6-ACTIF.

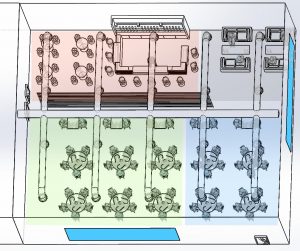

Figure 2. A restaurant with 90 people seating capacity and 22 ft high ceilings was used for the CFD simulation

Space configuration and conditions

A total of 20 diffusers are supplying 21,180 cfm of air in the entire restaurant, 1059 cfm per diffuser. The diffusers are installed on 16” ducts. The modelized space is an open concept restaurant with a 90 people seating capacity. The dimension of the room is 100 feet x 60 feet (40 m x 18 m), with 22 ft (6.7 m) ceilings. The open concept ceiling has visible ducts, and the diffusers are installed 6 feet (1.82 m) below the ceiling, 16 feet (4.88 m) above the floor.

Because standard diffusers and thermodynamic diffusers both supply cold air horizontally along the ceiling, a similar performance without efficiency gain was assumed in air conditioning mode. AX6’s swirl air diffusion pattern can improve air mixing compared to non-swirl diffusers, however this feature was disregarded in the current case study by using swirl diffusers in both scenarios.

The CFD simulation considers winter conditions in the northern half of North America, with an outside temperature of 14⁰F (-10⁰C). The supplied air temperature of the heating system is 90⁰F (32⁰C). Natural body heat gain from seated occupants (91.4⁰F or 33⁰C) and heat loss from the walls and single-glass windows were considered.

The Simulations

In order to limit the necessary computing resources and to accelerate the simulations, the room was divided into four sections. Simplified simulations were executed in each section and the results were compared. The bar section (top left, colored in red in Figure 4) has no significant source of heat loss and was the warmest. The smaller blue section, near the door and between the two large windows, was the coldest section. The green section with six tables and one window was the most representative and very close to the restaurant’s average, therefore that section was retained for in-depth simulations.

A total of three simulations were executed and analyzed, comparing three different solutions.

- The first simulation used only swirl diffusers supplying hot air horizontally;

- The second simulation combined the same diffusers with eight (8) ceiling fans. A common fan model’s specifications were used for the simulation;

- The third simulation used AX6-ACTIF thermodynamic diffusers configured in heating mode.

Simulation Results – Temperature

In the current case study, two important heights were retained for temperature measurements. The first height is the seated occupants’ head level, at 1.1 m or 43”, a very important temperature for thermal comfort. The same height was used for the thermostat readings, which commands the system and has a direct impact on energy consumption.

The second height considered was seated occupants’ ankle height, at 0.1 m or 4”. These measurements were considered strictly for thermal comfort. In order to follow ASHRAE’s requirement for seated occupants’ comfort, the temperature difference between 1.1m and 0.1m must be 3 degrees Celsius or less.

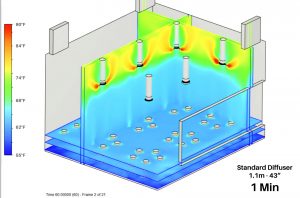

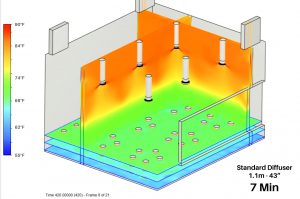

The simulation results show temperature colors on two vertical planes below the diffusers, as well as on three horizontal planes at respective heights of 0.1m, 0.6m and 1.1m.

In each simulation, initial room temperature is below 55⁰F or 12.8⁰C. The temperature is measured after each minute of running the HVAC system with a supplied air temperature of 90⁰F. A temperature bracket considered ideal in this scenario is between 68⁰F and 74⁰F – between 20⁰C and 23.4⁰C –, represented in green in the CFD results.

Standard Diffusers

Standard diffusers supply hot air horizontally, therefore hot air quickly rises towards the ceiling when exiting the diffusers in a cold room, as shown in Figure 5 after the first minute of simulation.

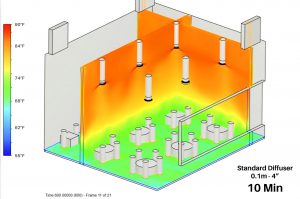

It took a total 7 minutes before a stable state between 68⁰F and 74⁰F at the thermostat level was reached, as shown in Figure 6. This is the value retained for the energy consumption comparison.

Also, after 7 minutes, strong air stratification is noticeable with an air temperature of 87⁰F or 31.6⁰C near the ceiling. Simultaneously, the temperature at occupant’s ankle height is still too cold for thermal comfort requirements.

It took a total of 10 minutes to reach an acceptable level of thermal comfort with standard diffusers, with a temperature difference of exactly 3⁰C as show in Figure 7.

Figure 6. It took 7 minutes to reach a comfortable temperature at the thermostat height with standard diffusers

Standard Diffusers with Ceiling Fans

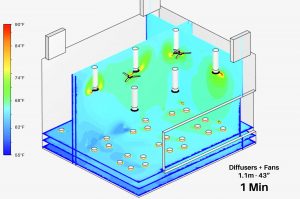

Figure 8. Ceiling fans help push hot air down into the occupied space as soon as the simulation starts

When adding ceiling – or destratification – fans to standard diffusers, hot air is forced downwards into the occupied space. Warmer spots near 68⁰F are noticeable in the first minute of simulation, as illustrated in Figure 8. This translates into a faster temperature improvement in the occupied space.

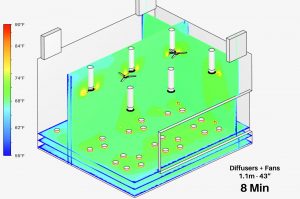

However, because of the intensified air movement in the room, it took longer (8 minutes instead of 7) to reach a stable comfortable temperature at the thermostat level with fans than without fans.

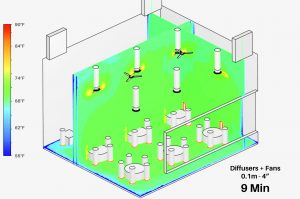

A comfortable temperature at ankle level was reached in only 9 minutes, with a delta temperature of 2.5⁰C between 1.1 m and 0.1 m height.

Figure 10. Occupants’ thermal comfort was reached in 9 minutes with the combination of standard diffusers and ceiling fans

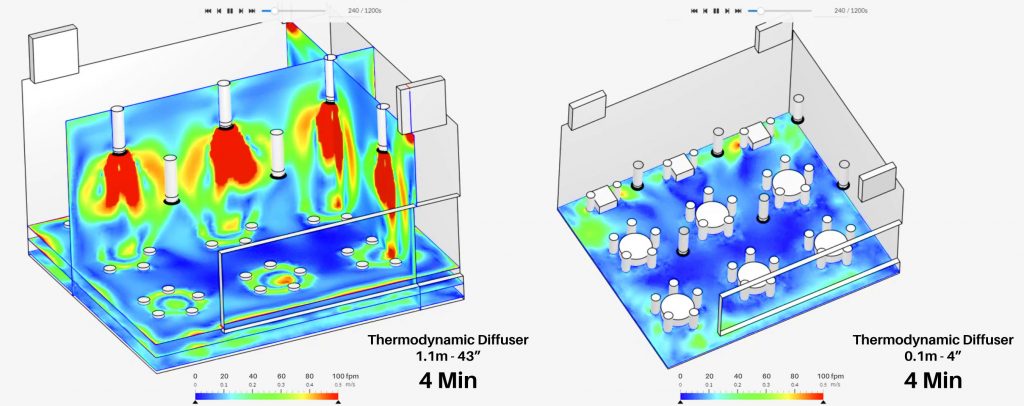

Thermodynamic Diffusers

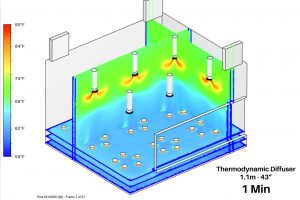

Figure 11. Hot air tends to rise when first coming out of thermodynamic diffusers, because of the difference in air density

Although thermodynamic diffusers supply heated air with a downward jet, the difference in air density causes hot air to rise in the first minute after starting the system.

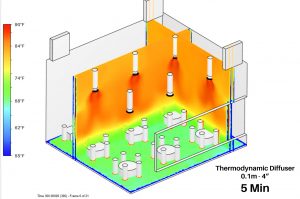

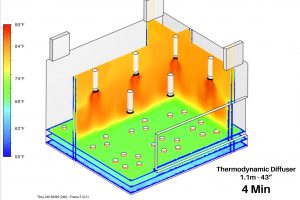

However, as the difference in air density diminishes, the supplied heated air maintains its downwards direction. It took only 4 minutes to reach a stable comfortable temperature at the thermostat level with thermodynamic diffusers.

Occupants would feel thermal comfort with a temperature difference of 2.35⁰C between their head and their ankles after only 5 minutes.

Figure 12. A stable temperature at the thermostat was reached after only 4 minutes with thermodynamic diffusers

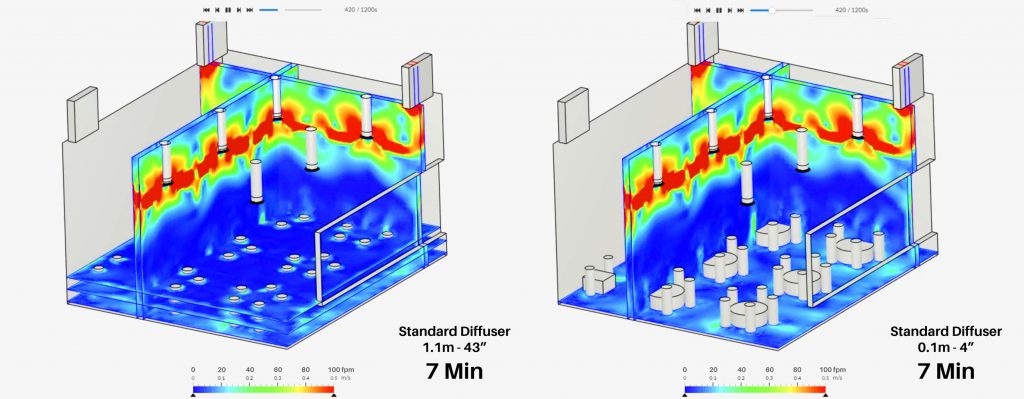

Simulation Results – Air Velocity

During the same simulations, air velocity was also measured in order to analyse its impact on occupants’ thermal comfort and also on indoor air quality. The perfect balance is sometimes difficult to obtain. In a restaurant setting, an ideal air velocity in the occupied space would range between 20 and 60 feet per minute in heating. A higher air velocity would cause air draft related discomfort, while an air velocity less than 20 fpm would be insufficient in order to properly ventilate the occupied zone. Ensuring proper ventilation in a restaurant is very important for customers’ safety. It helps reduce the risk of airborne diseases transmission and evacuate other harmful particles. Another benefit is ensuring a more pleasant customer experience by removing odors within the space.

Standard Diffusers

With standard diffusers, most of the air movement happens between the diffusers and the ceiling. As shown in Figure 14, after 7 minutes and when we have reached a stable temperature at the thermostat level, the air velocity varies between 0 and 10 fpm at the 1.1m height corresponding to people’s head. This is great for thermal comfort because occupants won’t feel any air draft, however, air mixing is almost inexistent and does not provide proper indoor air quality.

At occupants’ ankle level or 0.1 m, the air mixing is slightly better but still insufficient, varying between 0 and 20 fpm.

Figure 14. Air velocity in the occupied space with standard diffusers is good for thermal comfort, but not for indoor air quality

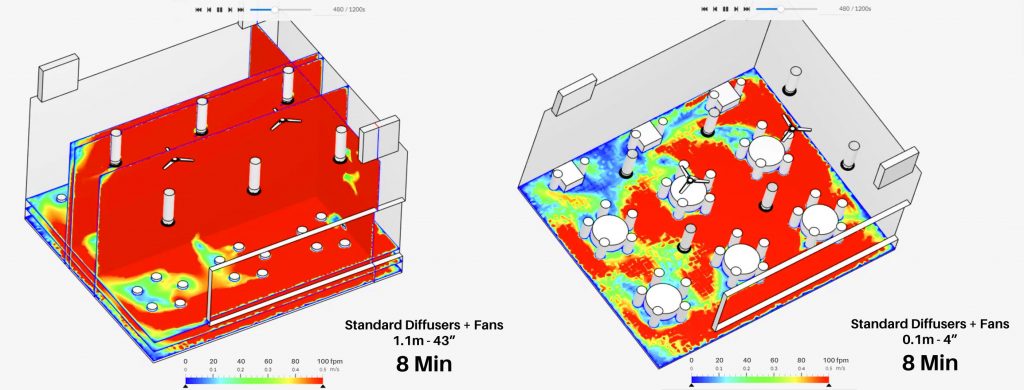

Standard Diffusers with Ceiling Fans

With ceiling fans, the air velocity is at 100 fpm or above in most of the occupied space, either at 0.1 m or 1.1 m. Such air mixing will ensure good ventilation and indoor air quality, however, high velocity air drafts above 100 feet per minute will cause serious thermal discomfort.

Figure 15. With ceiling fans, air velocity is at 100 fpm or above in most of the occupied space, which is good for IAQ but high velocity air drafts will create thermal discomfort

Thermodynamic Diffusers

After 4 minutes of system runtime – once a stable thermal comfort temperature has been reached at the thermostat level – the air velocity in most of the occupied space is between 20 and 60 feet per minute. Although there are some lower air velocity zones between the tables and higher velocity spots below the diffusers, the overall balance between thermal comfort and indoor air quality is much better than in the two previous simulations.

Figure 16. Air velocity is between 20 and 60 fpm in most of the space with Thermodynamic Diffusers, ensuring a good balance between thermal comfort and IAQ

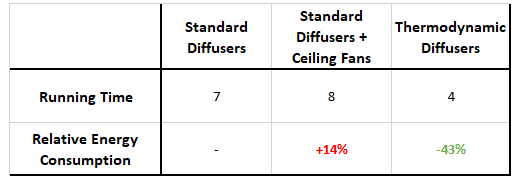

Energy Consumption Analysis

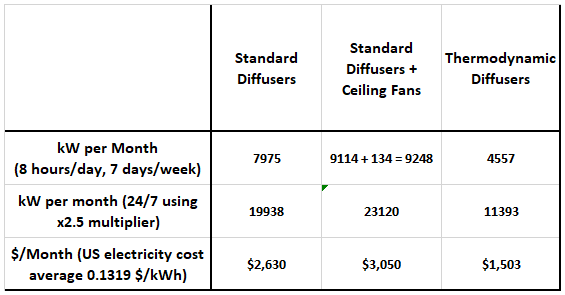

Considering that the thermostat reading controls the HVAC system, it can be assumed that energy consumption is proportional to how long it takes to reach the desired temperature at the thermostat height. Table 1 shows the running time required to reach a stable comfortable temperature, as well as the relative energy consumption compared to standard diffusers.

Table 1. Energy consumption – comparing the solutions

Although ceiling fans helped heating the occupied space faster compared to ceiling diffusers only, the impact of added air movement on thermostat readings resulted in a 14% extra energy consumption with ceiling fans. Furthermore, this number only considers the HVAC system’s energy consumption. The relative energy consumption percentage will increase once ceiling fans’ electric consumption is added to the HVAC system’s consumption.

Thermodynamic diffusers showed a significant energy efficiency improvement, reducing the load on the HVAC system by 43% compared to standard diffusers when heating from high ceilings.

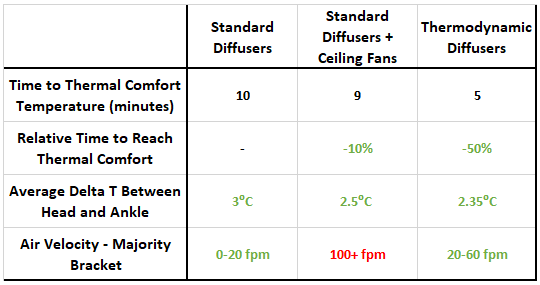

Thermal Comfort Analysis

In order to analyze thermal comfort, we must consider two parameters: temperature and air velocity. In this simulation, it was possible to reach a stable thermal comfort state with standard diffusers only, however it took longer to achieve than with ceiling fans or thermodynamic diffusers. Also, with higher ceilings or an increased number of heat loss sources (i.e. larger windows and/or more windows), it might have been impossible to reach the desired temperature only with standard diffusers.

Table 2. Thermal comfort – comparing the solutions

Adding ceiling fans helped reach the occupied space with heated air right away, and also reduced by 10% the amount of time required to reach a stable state of thermal comfort. A smaller temperature difference between their head and ankles will also result in the improvement of occupant’s thermal comfort. However, the high velocity air drafts caused by the combination of the diffusers and ceiling fans will create serious thermal discomfort which might offset the previous benefits.

The simulation using thermodynamic diffusers reached a stable thermal comfort state in only 5 minutes, 50% less time than it took to reach the same state with standard diffusers. The temperature difference between occupants’ head and ankles is also lower at 2.35⁰C and the majority of the occupied space has air velocity ranging between 20 and 60 feet per minute.

Indoor Air Quality Analysis

The combination of standard diffusers with ceiling fans created high velocity air drafts of 100 feet per minute or more in most of the occupied space, which is problematic in terms of thermal comfort. However, the resulting air mixing will ensure optimal air changes per hour and faster removal of odors, gases, airborne microbes, and other contaminants. Indoor air quality in the occupied zone is the best with ceiling fans.

Thermodynamic diffusers offered overall acceptable air mixing with an air velocity ranging between 20 and 60 feet per minute in the majority of the occupied space.

Air mixing in the occupied space was insufficient when heating with standard diffusers. In ASHRAE Standard 62.1, Table 6-4: Zone Air Distribution Effectiveness, an Ez correction factor of 0.8 is recommended for applications with ceiling supply of warm air 15°F (8°C) or more above space temperature and ceiling return. When applying the Ez factor of 0.8, the minimum ventilation rate for the room is increased to compensate for the inefficiency caused by air stratification. However, in a case like this with very high ceilings, such a correction factor does not reflect the reality and the increased Air Changes Per Hour is mostly happening near the ceiling and not in the occupied space.

The main objective of this case study was to analyze and compare the energy consumption of the three systems. However, the indoor air quality concern in a case where there’s a high level of stratification should be considered as important as energy consumption, mostly in a post COVID-19 pandemic world.

Economical Analysis

To compare the return on investment of each solution, both the energy cost and installed cost of each system had to be considered.

Energy Cost

When calculating the energy cost of standard diffusers with ceiling fans, the fans’ energy consumption (134 kW) had to be added to the HVAC System’s energy consumption (9114 kW). When calculating the 24-hours consumption, a 2.5 multiplier was used assuming that the thermostat would be set to a lower temperature outside of business hours.

Table 3. Monthly energy consumption for each solution

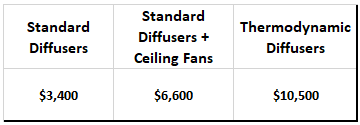

Installed Cost

The total installed cost includes materials cost and installation costs for the diffusers and fans. In the case of ceiling fans, an electrician’s cost to run power to the fans was also taken into account.

Table 4. Total installed cost

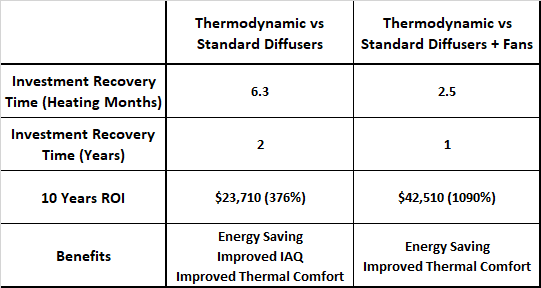

Thermodynamic Diffusers vs. Standard Diffusers

The total installed cost difference between thermodynamic and standard diffusers is $7,100.

The cost savings using thermodynamic diffusers versus standard diffusers is $1,127 per winter month.

Therefore, in this scenario, it would take 6.3 winter months (approximately two years) to recover the extra investment when comparing thermodynamic versus standard diffusers, based on energy consumption only.

The return on investment of thermodynamic diffusers versus standard diffusers after 10 years is $26,710 or 376%.

Thermodynamic Diffusers vs. Standard Diffusers and Ceiling Fans

The total installed cost difference between thermodynamic and standard diffusers with ceiling fans is $3,900.

The cost savings using thermodynamic diffusers versus standard diffusers with fans is $1,547 per winter month.

Therefore, in this scenario, it would take 2.5 winter months (less than one year) to recover the extra investment when comparing thermodynamic versus standard diffusers with fans, based on energy consumption only.

The return on investment of thermodynamic diffusers versus standard diffusers with fans after 10 years is $42,510 or 1090%.

Table 5. Return on Investment and other benefits

Interpreting the results

The current simulation was made in heating only, assuming that the energy consumption would be similar for all systems when cooling or ventilating the space. It is important to note that the outside temperature in these simulations was 14⁰F (-10⁰C). The calculated energy savings may be lower in states with warmer outside temperatures when heating in the winter.

Numerous other factors can also affect these numbers, for instance the dimension of the room, the ceiling height, the installation height of the diffusers, the insulation grade of the walls and windows, the number of windows and their dimensions, the number of occupants in the room, and the intensity and direction of sunlight.

Conclusion

In this case study, CFD simulations were used to compare the performance of standard diffusers vs standard diffusers with ceiling fans vs thermodynamic diffusers, when heating a restaurant with high ceilings.

Thermodynamic diffusers showed significant energy savings compared to standard diffusers only (43%) and standard diffusers with ceiling fans (50%).

When comparing thermodynamic diffusers to standard diffusers, the time to recover the extra investment is 6.3 winter months, or approximately two years based on 3 months of winter per year. The ROI after 10 years is $26,710 or 376%.

When comparing thermodynamic diffusers to standard diffusers combined with ceiling fans, the time to recover the extra investment is 2.5 winter months, or less than one year based on 3 months of winter per year. The ROI after 10 years is $42,510 or 1090%.

Thermodynamic diffusers also showed significant gains in terms of thermal comfort, reaching a stable comfort temperature in half the time required by standard diffusers and reducing the temperature difference between seated occupants’ head and ankles by 22%. The combination of standard diffusers and ceiling fans created high velocity air drafts in the occupied space, exposing customers to feeling serious thermal discomfort.

When analyzing air change effectiveness for indoor air quality, standard diffusers failed to properly mix the air in the occupied zone. The system failed to achieve the minimum ventilation requirement for occupants’ safety. While the high velocity drafts caused by the addition of ceiling fans and standard diffusers created serious thermal comfort problems, air mixing is more than optimal for proper indoor air quality.

Thermodynamic diffusers provided the best balance between thermal comfort, IAQ and energy consumption.

The Case Study can be downloaded in a PDF file at this link: https://effectiv-hvac.com/download/Case-Study-Energy-Efficiency-Thermodynamic-Diffusers-EffectiV-HVAC.pdf

About EffectiV HVAC Inc.

EffectiV HVAC manufactures and supplies high-performance architectural diffusers to improve ventilation in commercial and institutional buildings. EffectiV’s innovative diffusers help improve thermal comfort, energy efficiency and indoor air quality in a wide variety of applications. Their appealing designs bring a perfect balance between architectural requirements and mechanical engineering objectives.

Products include high induction swirl diffusers, linear diffusers, nozzle jet diffusers, adjustable diffusers, thermodynamic diffusers, UV Diffusers and constant air volume dampers.

About the Authors

Francois Godbout, President and founder of the company, combines 16 years of experience specialized in commercial air diffusion, with special interests in thermal comfort, energy efficiency and indoor air quality. Graduated from ETS in Montreal, Qc with a bachelor degree in Automated Production Engineering and from EPF in Sceaux, France, with a master degree in Automation.

Vishalkumar Patel has a master degree from Concordia University in Mechanical Engineering and is specialized in HVAC Design and Analysis, Thermodynamics, Heat Transfer and Computer Fluid Dynamics.