Product Description

AXO-TWIN Dual Flow High Induction Swirl Diffuser by EffectiV HVAC™ and MADEL® is designed to achieve greater air mixing, thermal comfort and energy efficiency in VAV installations.

AXO-TWIN provides an optimal performance for air volumes varying between 70 cfm and 320 cfm

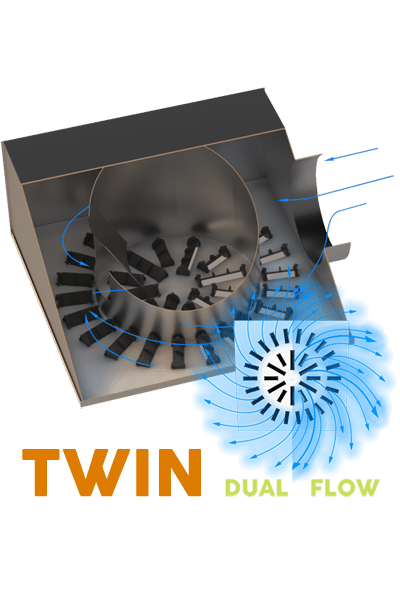

Thanks to the innovative and patent pending design of its dual chamber plenum, AXO-TWIN diffuser self-adjusts in order to let the air pass through more or fewer induction vanes based on the volume of air, resulting in a more stable performance in VAV applications.

At low cfm, the air is diffused through the outer circle of induction vanes. At high cfm, the inner chamber opens and the air is diffused through the entire surface of the diffuser.

The adjustment is completely autonomous and doesn’t require any special configuration, controls nor electricity.

The direct outcome is a more stable throw, air velocity and induction ratio in VAV applications.

When designing a system, engineers select diffusers based on maximum air volume, trying to reach the occupied zone with limited air velocity to properly mix the room air while avoiding thermal discomfort. When VAV systems supply lower air volumes, however, the diffusion performance is seriously affected. At lower velocity, cold air tends to drop from the ceiling and hot air tends to stick to the ceiling. Hot and cold spots are created in the room and the air may fail to reach to occupied zone. Energy consumption and occupants’ comfort are automatically impacted. The lack of air mixing may also increase the concentration of contaminants – CO2, gases, viruses and other airborne particles – accumulated in the room’s air.

With AXO-TWIN, we limit the diffuser’s free area in order to ensure enough discharge velocity to maintain a higher discharge velocity, a higher induction ratio and more stable throw distances at low cfm.

The ultimate benefits are: significantly increased thermal comfort, energy efficiency, and improved ventilation for indoor air quality.

The high induction vanes and pressurization of the air in the plenum create a very even swirl diffusion pattern by default. The vanes are individually adjustable to make it possible to adapt the airflow.

AXO-TWIN diffusers allow an optimal performance despite flow variations of up to 75% while keeping the air stream stable. For optimal conditions, AXO- TWIN diffusers may be used in ceilings 8.5 up to 13 feet (2.6 up to 4 meters) high, with a temperature differential up to 27ºF (15ºC).

With AXO-TWIN, we’re taking high induction diffusers to the next level.